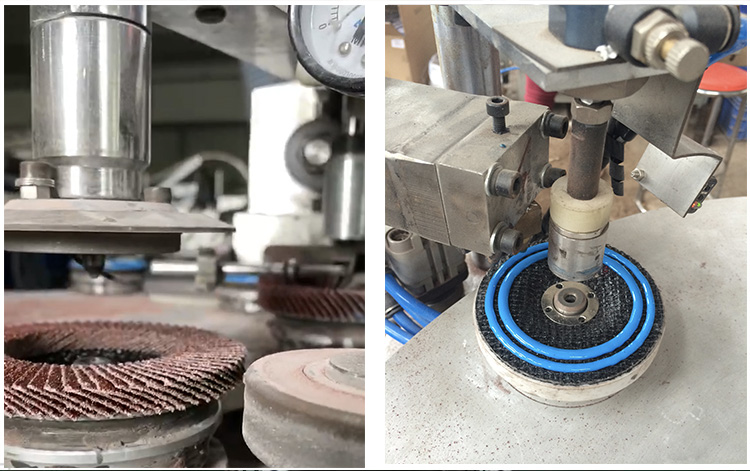

Automatic flap disc machine is developed specifically for the production of abrasive flap disc and non-woven flap disc. The machine can auto pick the backing, detect backing, auto quantitative gluing, cut & put flaps, shaping and auto pick up finished flap disc, with high degree of automation, remote monitoring and maintenance, uniform flap arrangement, improved efficiency and stable quality. It can produce 6000pcs per 8 hours for single operator.

Basic specification |

Flap disc size | Backing: φ75mm-φ180mm Flap width: 11mm-35mm | Glue qtty | 4-30g (±0.5g) |

Flap disc Type | T27/T29 Single/Double flap | Flap qtty | Can be put flap at any degree |

Backing | Fiberglass, plastic | Production capacity | 6000P/8H |

Power | Panasonic servo motor | Operator | 1 |

Power supply | Pneumatic, Electric | Voltage | 380V |

Glue pump | 280KG | Installed power | 8KW |

Glue system | Airtac cylinder, SMC Balance control valve | Feeder size | 1000mm*400mm*1400mm |

Glue system size | 1100mm*560*1600mm | Main machine size | 2200mm*1600mm*1500mm |

Photoelectric sensor | Autonics | Cylinder | Airtac |

Magnetic switch | Airtac | Control panel | Weinview |

Air switch | CHINT | Temp. controller | OMRON |

Reducer | Liming | Bearing | FAG |

Bearing | NSK | PLC | Taida |

Linear guide rail | Hiwin | Pneumatic component | SMC

|